- This topic is empty.

-

AuthorPosts

-

September 15, 2025 at 6:16 pm #111385

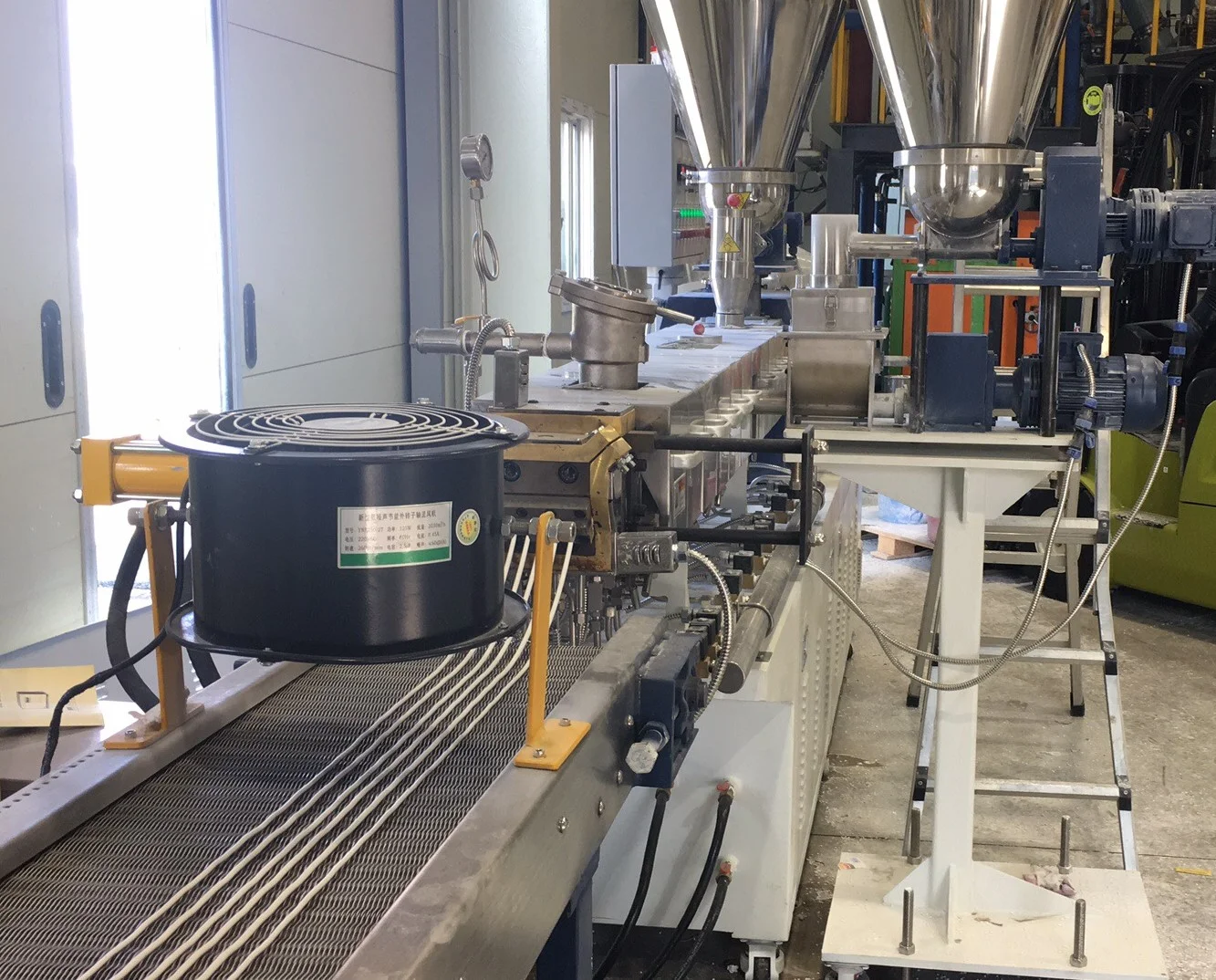

In the plastic processing industry, efficiency, precision, and reliability are critical for achieving consistent product quality. One of the most important machines in modern pelletizing lines is the Air Cooling Strand Pelletizer System. This system is designed to cut plastic strands into uniform pellets while using air cooling technology to ensure stable operation and high-quality output. For manufacturers in extrusion, compounding, and recycling, adopting this system can significantly enhance production performance.

Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. is a leading enterprise committed to innovation in the machinery industry. With advanced expertise in extrusion, plastic compounding, and pelletizing equipment, the company develops state-of-the-art solutions—such as air cooling strand pelletizer systems—that meet the growing demands of manufacturers worldwide.

1. Energy-Efficient Cooling Technology

Unlike traditional water cooling, an air cooling strand pelletizer system uses air circulation to cool plastic strands before pelletizing. This eliminates the need for extensive water treatment, saving energy and reducing operational costs. It also avoids problems such as water contamination, making it a cleaner and more eco-friendly choice.

2. High-Quality Pellet Output

Consistent pellet shape and size are essential for downstream processing in industries such as film blowing, injection molding, and extrusion. The air cooling process minimizes strand deformation and ensures smoother pellet surfaces, resulting in higher quality pellets that improve production stability.

3. Reduced Maintenance and Operation Costs

Water-cooled systems often require filtration, water circulation pumps, and chemical treatment to prevent scaling. In contrast, air cooling reduces auxiliary equipment needs and simplifies maintenance. This translates to lower long-term operating costs and increased uptime.

4. Ideal for Sensitive Polymers

Certain polymers are sensitive to water and can easily absorb moisture during pelletizing. An air cooling system prevents direct water contact, making it ideal for materials such as engineering plastics, biodegradable resins, and specialty compounds. This ensures material integrity and enhances product performance.

5. Compact and Space-Saving Design

Air cooling strand pelletizer systems are generally more compact than water-cooled lines, as they require fewer auxiliary tanks and pipes. This makes them suitable for manufacturers who want to optimize factory space without sacrificing production efficiency.

6. Eco-Friendly and Sustainable

With growing emphasis on sustainable manufacturing, air cooling technology helps reduce water consumption and wastewater discharge. Companies that adopt this system contribute to environmentally responsible production practices, aligning with global trends in green manufacturing.

7. Versatile Applications Across Industries

From foamed extrusion to plastic compounding, the air cooling strand pelletizer system can handle a wide range of materials and applications. Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. designs these systems to meet the requirements of various industries, ensuring reliable performance in both small-scale and large-scale operations.

Conclusion

The Air Cooling Strand Pelletizer System represents a major step forward in modern plastic pelletizing. With benefits such as energy efficiency, superior pellet quality, reduced maintenance, and environmental sustainability, it has become the preferred choice for manufacturers seeking advanced production solutions.

As a pioneer in the machinery sector, Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. continues to deliver innovative pelletizing technologies that empower companies to achieve higher efficiency, lower costs, and better product quality. Choosing the right pelletizing system is not just about today’s production—it is about preparing for the future of sustainable and intelligent manufacturing.

http://www.kaifengmachine.com

Jiangsu Kaifeng Xinye Intelligent Equipment Co., Ltd. -

AuthorPosts

- You must be logged in to reply to this topic.