- This topic is empty.

-

AuthorPosts

-

September 15, 2025 at 6:17 pm #111389

Efficient mold maintenance is critical for any manufacturing operation. Over time, residue, scale, and debris can accumulate in mold waterways, leading to reduced cooling efficiency, longer cycle times, and potential product defects. Investing in a high-quality mold waterway cleaning machine is essential to ensure consistent production quality, extend mold life, and minimize downtime.

This guide will help you select the right cleaning machine for your factory’s specific needs.

Why Mold Waterway Cleaning Is Important

Mold waterways, responsible for circulating coolant during the molding process, are prone to clogging from mineral deposits, rust, and other contaminants. Neglecting regular cleaning can cause:

-

Inefficient cooling and uneven mold temperatures

-

Increased energy consumption

-

Shortened mold lifespan

-

Higher defect rates in molded products

A dedicated mold waterway cleaning machine ensures these channels remain clear, allowing your production to maintain optimal efficiency.

Key Factors to Consider When Selecting a Mold Waterway Cleaning Machine

1. Cleaning Method

Different cleaning technologies are available, including:

-

Chemical flushing: Uses specialized solvents to dissolve scale and residue.

-

Ultrasonic or electrolytic cleaning: Ideal for precision molds with intricate channels.

-

Dry ice or laser cleaning: Effective for surface residues without using chemicals.

Selecting the right method depends on the type of contaminants, mold material, and factory environmental considerations.

2. Mold Compatibility

Check that the machine can handle your molds’ size, material, and complexity. High-quality machines are adaptable, providing efficient cleaning for molds of varying dimensions and internal geometries.

3. Cleaning Efficiency and Cycle Time

Production demands often dictate the speed at which molds can be cleaned. Choose a machine with sufficient flow rate, pressure, and cleaning cycle efficiency to minimize downtime while maintaining thorough cleaning.

4. Automation and Control

Advanced machines come with automated controls, adjustable parameters, and monitoring systems. Features like programmable cleaning cycles and real-time system diagnostics improve accuracy, safety, and repeatability.

5. Maintenance and Reliability

A robust cleaning machine should require minimal maintenance while offering long-term reliability. Consider manufacturers with proven track records in delivering durable, high-performance equipment.

Why Choose Guangzhou Yizai Intelligent Technology Co., Ltd.

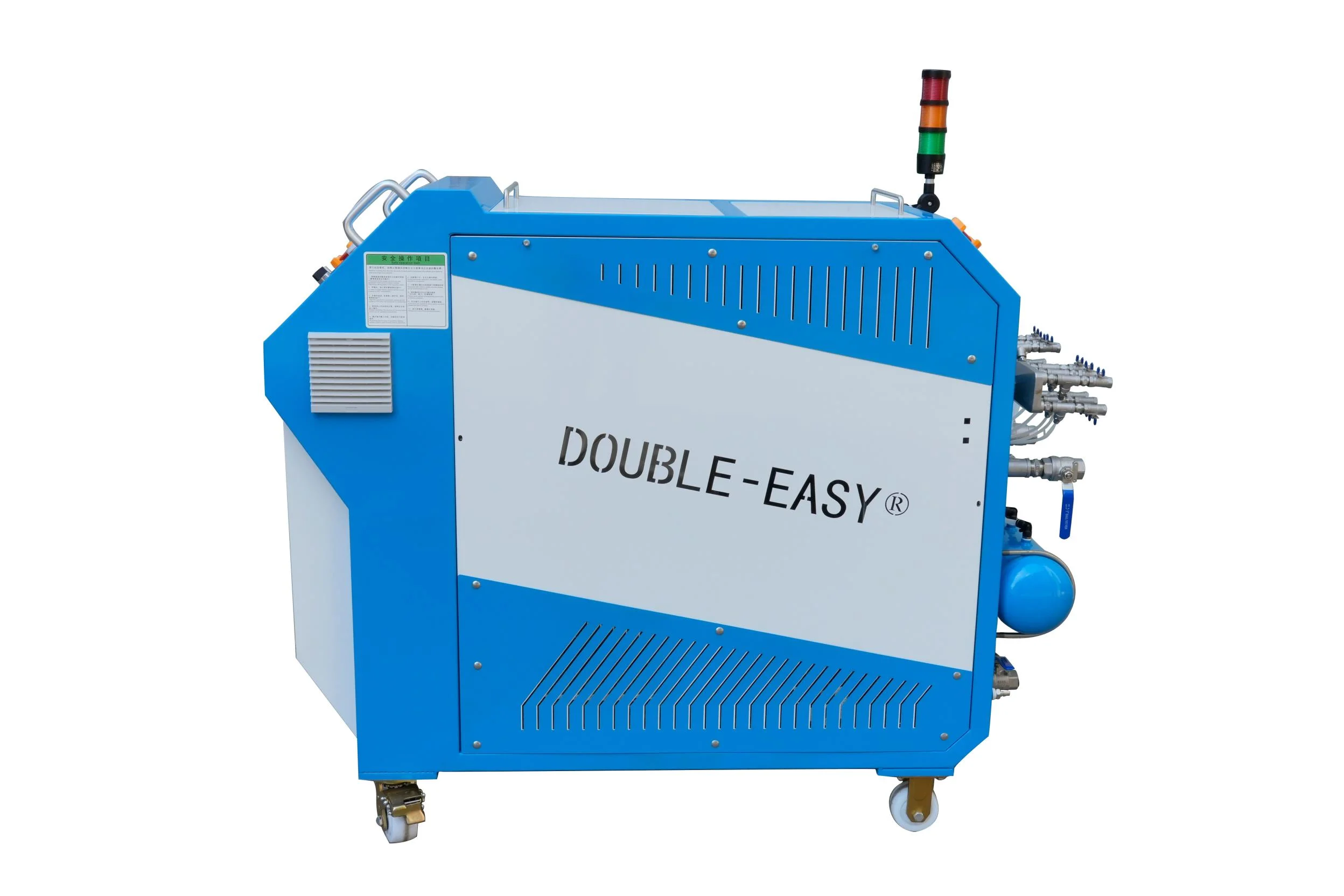

For factories looking for reliable, innovative solutions, Guangzhou Yizai Intelligent Technology Co., Ltd. stands out as a global leader. As a high-tech enterprise integrating R&D, production, sales, and service, Yizai specializes in a wide range of advanced cleaning and energy management equipment, including:

-

Mold waterway cleaning machines

-

Dry ice cleaning machines

-

Laser cleaning machines

-

Ultrasonic electrolytic cleaning machines

-

Circulating water electronic pulse descaling systems

-

DBAI energy-saving management systems

Yizai’s products combine cutting-edge technology, precision engineering, and energy efficiency, providing tailored solutions for industrial manufacturers. With a focus on high-quality production, comprehensive after-sales support, and innovative R&D, Yizai ensures your molds are cleaned safely, effectively, and efficiently.

Conclusion

Selecting the right mold waterway cleaning machine is crucial for maintaining mold efficiency, reducing downtime, and improving product quality. By evaluating cleaning methods, mold compatibility, efficiency, automation features, and manufacturer reliability, you can make a choice that optimizes your production process.

Partnering with Guangzhou Yizai Intelligent Technology Co., Ltd. ensures access to industry-leading technology, durable equipment, and expert support—helping your factory maintain high-performance molds and consistent production outcomes.

http://www.moldcleanmachine.com

Guangzhou Yizai Intelligent Technology Co., Ltd -

-

AuthorPosts

- You must be logged in to reply to this topic.