- This topic is empty.

-

AuthorPosts

-

November 6, 2025 at 11:33 am #111684

If you want a kerosene stove OEM partner who can deliver a market-ready product from concept to mass production — covering design, safety, verification, packaging and logistics — you need a partner who understands the product as deeply as the market. This guide walks you through every aspect of OEM kerosene stove development with INBESTCAMP: from inner components and combustion characteristics to factory processes, certification, cost structure and commercialization strategy.

Executive summary (what you’ll learn)

-

Core design & combustion principles that determine stove performance and safety.

-

Material, parts and manufacturing decisions that drive durability and cost.

-

Key safety features and test protocols buyers must insist on.

-

Customization possibilities for branding, functionality and market segmentation.

-

Certification, packaging, logistics and after-sales considerations for global distribution.

-

Commercial factors: pricing drivers, MOQ, lead time, warranties and marketing hooks.

Tuoshenghe brings 15+ years of industry experience, vertical manufacturing and intelligent production to deliver OEM/ODM kerosene stoves engineered for performance, safety and brand differentiation.

1. Product anatomy — inside out (component-level breakdown)

Understanding the parts clarifies where quality matters and where you can optimize cost.

1. Burner assembly

-

Burner head (jet/nozzle geometry): controls spray pattern and vaporization—key for clean combustion.

-

Vaporizer tube (preheating path) on pressurized models: ensures kerosene vaporizes before mixing with air.

2. Fuel tank & pump

-

Material: stamped stainless steel or powder-coated cold-rolled steel.

-

Capacity options (0.5L–2L+) for portability vs runtime tradeoffs.

-

Pump: manual piston pump or integrated pressure pump with check valves.

3. Control valve & regulator

-

Precision brass valve for flame adjustment and metering.

-

Pressure regulator in pressurized stoves for stable output across temperatures.

4. Ignition system

-

Manual wick / match ignition or piezoelectric auto-igniter.

5. Support structure & pot stand

-

Foldable legs, trivet geometry for stability; thermal isolation from fuel tank.

6. Seals & gaskets

-

Viton or silicone seals (fuel-resistant) at joints to prevent leaks.

7. Safety features

-

Flame arrestor screens, overflow prevention, pressure relief valve (where applicable).

8. Finish & coating

-

Anti-corrosion coatings, high-temperature paints, optional chrome plating.

Why it matters: the burner and valve determine fuel efficiency & emissions; tank material and seals determine durability and safety; ignition and supports determine user experience.

2. Combustion types & performance tradeoffs

Kerosene stoves generally use one of two combustion architectures:

A. Pressurized (wickless/vapor) kerosene stoves

-

How it works: Pump pressurizes tank → kerosene forced through jet → preheated vapor mixes with air → atomized combustion.

-

Pros: High heat output, efficient, good for cold weather.

-

Cons: More complex (valve/pump maintenance), higher manufacturing precision required.

B. Wick-based kerosene stoves

-

How it works: Kerosene drawn by wick → burns as liquid on wick surface.

-

Pros: Simple, low cost, easy to repair.

-

Cons: Lower thermal efficiency, sootier, slower heat, less suitable for winter.

Performance metrics to evaluate

-

Heat output (kW / BTU) and useful cooking power.

-

Fuel consumption (g/hr or ml/hr at nominal power).

-

Boil time (e.g., 1 L water to boil).

-

Cold-start reliability and wind resistance.

-

Emissions: particulate and CO — critical for indoor/tent use.

INBESTCAMP engineers select combustion architecture based on target market (cold climate users favor pressurized stoves; budget or developing markets often accept wick models).

3. Materials, coatings and corrosion resistance

Outdoor gear must tolerate weather, rough handling and variable storage.

-

Tank & body: 304 stainless steel (best corrosion resistance) or coated CR steel (cost balance).

-

Burner head & nozzle: brass or stainless for dimensional stability under heat. Brass jets are common because they machine to tight tolerances and resist wear.

-

Seals: Viton for high temp/chemical resistance; silicone as lower-cost option.

-

Paints & finishes: high temp silicone paints, powder coatings with rust inhibitors.

-

Gaskets & packing: PTFE for fuel contact points if cost allows.

Specification tip: insist on material certificates and lab tests (salt spray, humidity) if selling to coastal markets.

4. Safety Engineering and Mandatory Testing

Safety cannot be compromised. For the purchasers of original equipment manufacturers, the testing matrix of the factory is the primary selection criterion.

Key Safety Features

-

Overpressure Relief Valve (pressurized model).

-

Leak-proof fuel connections and double sealing.

-

Stable pot body support with anti-slip geometric structure.

-

Cool-touch control area and protective device.

Recommended testing procedures:

-

Burning time and continuous operation tests at rated and maximum settings.

-

Carbon monoxide and particulate matter emission tests – crucial for the tent/heater market.

-

Drop and vibration tests to simulate transportation and field usage conditions.

-

Salt spray/corrosion tests for coastal exports.

The testing laboratory of Tongseng will conduct a comprehensive verification cycle and keep records for auditing and compliance purposes.

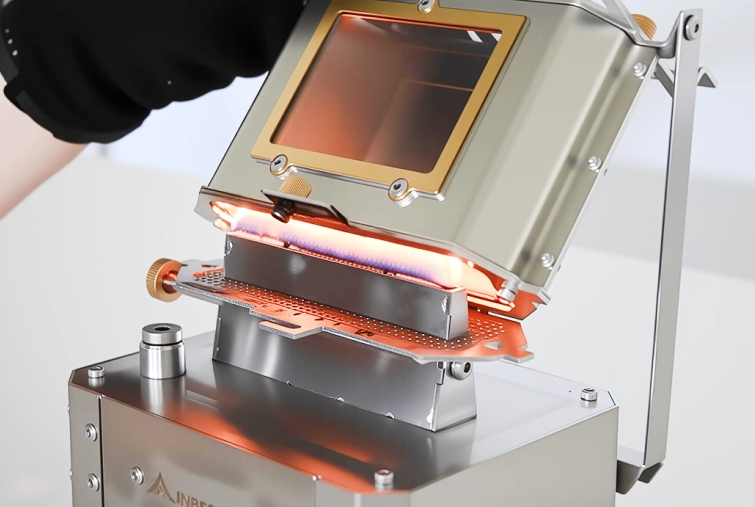

5. Manufacturing: processes, tolerances & quality control

Tuoshenghe’s value proposition is vertical integration and intelligent manufacturing.

Typical factory flow

1. Sheet forming & stamping → body/tank fabrication.

2. CNC machining for valves, burners, and precision parts.

3. Welding & brazing (for burner assemblies).

4. Surface treatment (passivation/powder coat).

5. Assembly line with leak & pressure testing stations.

6. Final functional burn test and packaging.

Quality control (QC) checkpoints

-

Incoming material inspection (MMR, certificates).

-

Dimensional inspection (CMM/projection).

-

Weld quality inspection (visual & X-ray if needed).

-

Functional bench test for each unit (burner stability, valve operation).

-

Batch sample lab tests (emissions, pressure).

Why intelligent manufacturing matters: automated cutting, robotic welding and inline testing reduce variance and lower defect rates (<1% target).

6. Customization & OEM options — how brands can differentiate

INBESTCAMP’s OEM offerings typically include:

AuthorPostsViewing 1 post (of 1 total)- You must be logged in to reply to this topic.

-