- This topic is empty.

-

AuthorPosts

-

September 15, 2025 at 6:22 pm #111394

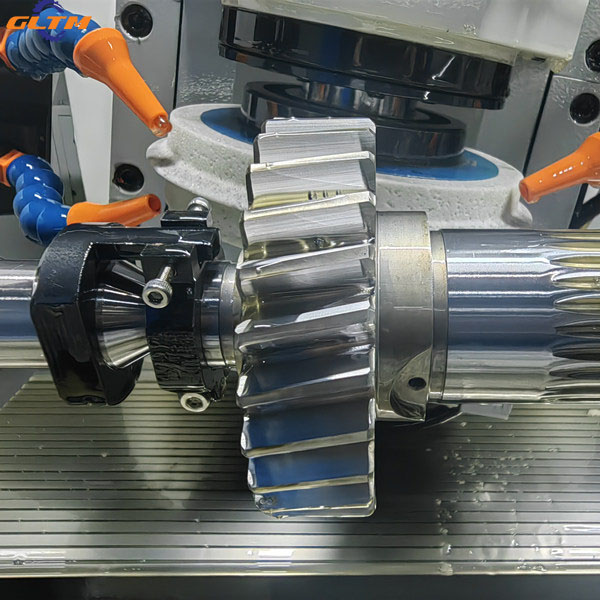

In modern manufacturing, precision and efficiency are more important than ever. One of the critical machines that ensure gears meet exact specifications is the CNC profile gear grinding machine. Whether you are producing gears for automotive, motorcycles, reducers, synchronous pulleys, or pumps, choosing the right machine will directly impact production quality and efficiency. This guide will walk you through everything you need to know when selecting the best CNC profile gear grinding machine for your business.

1. Why CNC Profile Gear Grinding Machines Matter

Gear performance depends on precision. Even the slightest error can result in noise, vibration, or premature wear. CNC profile gear grinding machines ensure gears are manufactured with:

-

High accuracy in tooth geometry

-

Superior surface finish

-

Consistent quality across large production runs

For industries like automotive and motorcycles, where reliability and performance are non-negotiable, having the right CNC gear grinding solution is essential.

2. Key Features to Look For

When choosing a CNC profile gear grinding machine, keep the following in mind:

-

High Rigidity: A strong machine structure ensures stable performance during high-load grinding operations.

-

High Efficiency: Look for machines designed for fast processing without sacrificing quality. This reduces cycle times and improves overall productivity.

-

Reliability: A reliable machine minimizes downtime and ensures consistent output.

-

Advanced CNC Control System: The CNC control system should be user-friendly, with precise programming and automation capabilities to handle complex gear profiles.

-

Versatility: The ability to handle different gear sizes, shapes, and materials is critical for manufacturers serving diverse industries.

3. Application Across Industries

CNC profile gear grinding machines are used across multiple sectors, including:

-

Automotive: For gears that must withstand high torque and long-term durability.

-

Motorcycles: Precision gears ensure smooth riding performance.

-

Reducers & Gearboxes: High-efficiency gears for industrial machinery.

-

Synchronous Belt Pulleys: Accurate grinding ensures proper timing and minimal slippage.

-

Pumps: Precision gears for fluid systems that require consistent flow and pressure.

4. Why Choose GLT Machinery (GLTM/GLT)

GLT Machinery (GLTM/GLT) is a leading manufacturer of CNC gear hobbing machines in China. With a design philosophy centered on high rigidity, high efficiency, and high reliability, GLT has successfully delivered customized gear manufacturing solutions to a wide range of industries.

By leveraging their expertise, customers benefit from:

-

Advanced gear manufacturing technology

-

Machines built for long-term performance

-

Tailored solutions that meet specific production needs

Whether you’re in the automotive sector or pump manufacturing, GLT’s CNC gear solutions help streamline production while ensuring gears meet the highest quality standards.

5. Tips for Making the Right Decision

-

Assess Your Production Needs: Consider gear types, production volume, and accuracy requirements.

-

Evaluate After-Sales Support: Reliable service and technical support are just as important as machine performance.

-

Look for Scalability: Choose a machine that can adapt to future production demands.

-

Consider Total Cost of Ownership: Efficiency and durability can save more money in the long run than just opting for the cheapest option.

Conclusion

Selecting the right CNC profile gear grinding machine is an investment in precision, efficiency, and long-term competitiveness. Companies like GLT Machinery (GLTM/GLT) have proven expertise in providing reliable, high-performance gear solutions tailored to customer needs.

Whether your business is in the automotive, motorcycle, or industrial machinery sector, the right CNC gear grinding machine will ensure your gears perform flawlessly—driving productivity and innovation in every rotation.

http://www.gltmachinery.com

Wuxi General Machinery Co., Ltd. (GLTM / GLT) -

-

AuthorPosts

- You must be logged in to reply to this topic.